The Generative Industrial Revolution: AI-Assisted Design and CAD Infrastructure in 2026

Executive Summary: The Transition to Algorithmic Engineering

As the engineering world crosses the threshold into 2026, the Computer-Aided Design (CAD) industry is undergoing its most significant transformation since the introduction of parametric modeling in the 1980s. The convergence of geometric deep learning, Large Language Models (LLMs), and GPU-native infrastructure has shifted the paradigm from "computer-aided" design—where software passively records human intent—to "AI-generated" design, where software actively participates in the creative and analytical process.

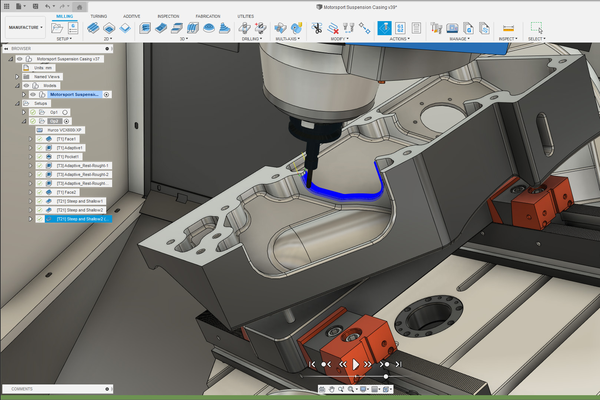

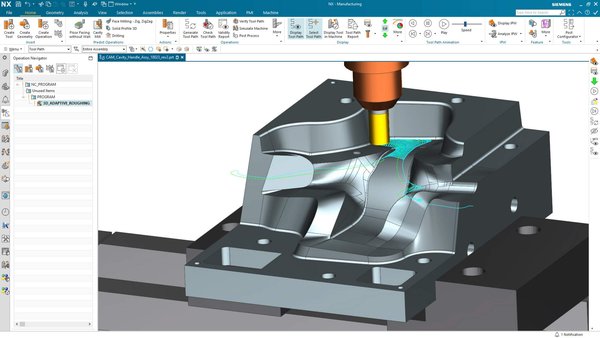

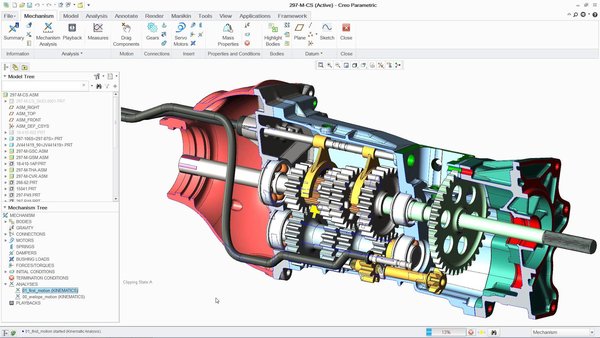

The landscape at the close of 2025 is defined by a dichotomy between "New Wave" infrastructure builders and "Legacy" ecosystem integrators. The former, led by Zoo.dev and AdamCAD, are reimagining the CAD technology stack from the ground up, utilizing API-first architectures and custom geometric kernels to bypass the limitations of decades-old software foundations. The latter, comprising industry titans like Autodesk, Dassault Systèmes, and Siemens, are aggressively deploying "Copilot" architectures—such as SolidWorks' Aura and Siemens' NX AI Chat—to layer intelligence on top of established, trusted workflows.

Key Distinction: Mesh vs. B-Rep

This analysis explores the critical distinction between "dumb" mesh generation and "smart" Boundary Representation (B-Rep), the automation of the documentation bottleneck via tools like DraftAid, and the rise of physics-informed AI through platforms like PhysicsX. 2026 will not be the year human engineers are replaced, but the year the "Hybrid Workflow" becomes the industry standard.

This comprehensive analysis dissects the technologies, market dynamics, and specific platforms driving the industry forward, exploring how AI handles the probabilistic generation of geometry and documentation while human engineers govern the deterministic validation of physics and manufacturability.

1. The Infrastructure of Innovation: Zoo.dev and the Headless Revolution

1.1 The Thesis: CAD as a Programmable Utility

The most profound structural shift in the 2025-2026 CAD landscape is the movement toward "headless" CAD infrastructure. Zoo.dev has emerged not merely as a software competitor but as a foundational utility provider, positioning itself as the "Stripe for hardware design". This analogy is deliberate and instructive: just as Stripe abstracted the complexities of banking protocols into accessible APIs for developers, Zoo is abstracting the immense mathematical complexity of geometric modeling into the KittyCAD Design API.

Historically, innovation in CAD was stifled by the high barrier to entry. Developing a new CAD application required licensing expensive, monolithic geometric kernels (like Parasolid or ACIS) that were architected in the era of single-core CPUs and desktop workstations. These kernels were never designed for the latency-sensitive, parallelized demands of the modern web or AI model training. Zoo's strategy addresses this bottleneck by rebuilding the stack.

1.2 The KittyCAD Design API and GPU-Native Geometry

The core of Zoo's technological moat is the KittyCAD Design API. Unlike legacy systems that rely on the CPU for geometric calculations, KittyCAD is built to run on Graphics Processing Units (GPUs).

- Parallelization and Speed: The shift to GPU-native processing allows for massive parallelization. In geometric modeling, operations like ray casting, boolean intersections, and lattice generation can be executed simultaneously across thousands of GPU cores. Zoo claims this architecture makes their software "unbelievably fast," a critical requirement when an AI model needs to generate and evaluate thousands of geometric variations in seconds.

- WebRTC Streaming: To deliver this power to the end-user, Zoo utilizes WebRTC video streaming. The heavy geometric lifting occurs on Zoo's enterprise-grade GPUs in the cloud, and the visual result is streamed to the client's browser with low latency. This decoupling of compute and display democratizes high-end CAD, allowing complex engineering work to be performed on low-power laptops or tablets.

- B-Rep Fidelity: A critical differentiator for Zoo is its strict adherence to Boundary Representation (B-Rep). In the generative AI boom of 2023-2024, many tools produced "meshes" (polygonal approximations made of triangles). While sufficient for gaming or visual effects, meshes are useless for precision manufacturing (CNC machining, injection molding). Zoo's engine operates on B-Reps—mathematically precise surfaces and curves—ensuring that the data generated via their API is ready for the factory floor without conversion artifacts.

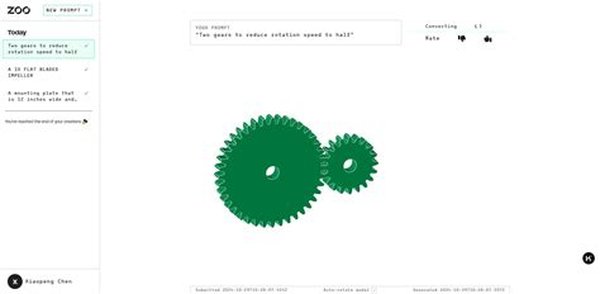

1.3 Text-to-CAD: The Flagship Implementation

While the API is the product for developers, Text-to-CAD is the capability that has captured the broader engineering imagination. Integrated into the Zoo Design Studio, this feature allows users to generate editable CAD models from natural language prompts.

Behind this capability lies ML-ephant, Zoo's suite of machine learning models trained specifically on engineering data. Unlike generic image generators (like Midjourney) that operate on pixels, ML-ephant "understands" the feature tree of a CAD model. When a user types "A flange with a 50mm diameter and 6 bolt holes," the system does not just "paint" a 3D shape; it constructs the geometric logic required to define that shape.

Zoo advocates for a workflow where AI is the "starter," not the "finisher." An engineer might use a text prompt to generate the base geometry of a bracket, saving 20-30 minutes of initial sketching and extruding. Once the base model is generated, the engineer takes over using traditional point-and-click tools or code to refine tolerances and fit. This acknowledges a crucial reality of 2026: AI is probabilistic (it makes a good guess), but engineering is deterministic (it requires exactitude).

1.4 The "Private Tenant" Security Model

One of the most significant barriers to AI adoption in engineering is Intellectual Property (IP) security. Manufacturing firms are fiercely protective of their design files, which contain the DNA of their competitive advantage. Zoo addresses this with an enterprise-grade "Private Tenant" model. They offer the ability to train Text-to-CAD models on a company's proprietary data in a siloed environment. This means a defense contractor or automotive firm can fine-tune the model on their own repository of parts without that data ever touching the public model weights. This "Zero-Retention" guarantee is a prerequisite for enterprise adoption in 2026.

1.5 Economic Analysis: The Consumption Model

Zoo's pricing model disrupts the traditional "seat license" economics of CAD. Instead of a flat annual fee per user, Zoo operates on a consumption basis, similar to cloud computing providers like AWS. The fundamental unit of currency in the Zoo ecosystem is the Zookeeper Credit, where 1 credit equals 1 second of GPU compute time.

The base rate is approximately $0.0083 per second of compute. A free tier provides roughly $10 worth of credits (1,205 seconds) per month, allowing students and hobbyists to experiment. Enterprise tiers scale this up, but the core philosophy remains: you pay for the work the computer does, not just for the right to access the software. This model is particularly attractive for automated workflows where a human user isn't physically present at the screen.

2. The Democratization of Design: AdamCAD and the Maker Revolution

2.1 The "Prompt-to-Prototype" Philosophy

While Zoo targets the infrastructure layer, AdamCAD has positioned itself as the user-centric champion for the "Maker" and rapid prototyping community. As of late 2025, AdamCAD is the most visible "B2C" (Business to Consumer) player in the AI CAD space, focusing on accessibility and speed over industrial complexity.

The platform explicitly caters to "Makers & Tinkerers," "STEM Educators," and mechanical engineers needing rapid "napkin sketch" equivalents. Its marketing emphasizes versatility, claiming to handle everything from "camshafts to key holders," positioning itself as the "Canva for 3D Modeling". AdamCAD runs entirely in the browser, removing the need for high-end workstations.

2.2 Features: From Conversation to Parameter

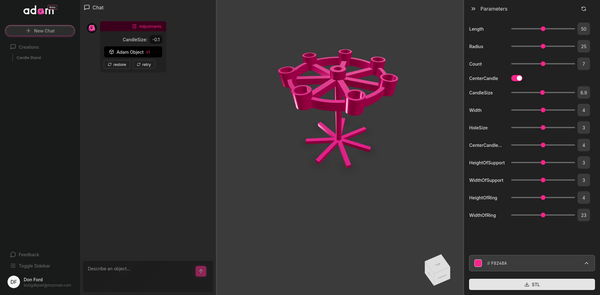

AdamCAD's primary innovation is the Conversational Interface. Users interact with the software through a chat window, describing their intent in natural language.

- Instant Refinement Mode: Early text-to-3D tools suffered from the "static output" problem—the AI would generate a shape, but if it was slightly wrong, the user had to regenerate the whole thing. AdamCAD solves this with "Instant Refinement." When a model is generated (e.g., a gear), the AI automatically identifies key variables (number of teeth, diameter, thickness) and creates parametric sliders for them. This allows the user to tweak the AI's output in real-time without re-prompting, effectively generating a parametric "mini-app" for that specific part.

- Image-to-Object Engine: Beyond text, AdamCAD allows users to upload reference images (JPG/PNG). The AI attempts to reconstruct the 3D geometry from these 2D inputs. While this feature is still maturing, it is invaluable for reverse engineering—users can photograph a broken part and get a starting point for a replacement 3D print.

- CAD Companion Mode: Recognizing that professionals cannot abandon their primary tools, AdamCAD offers plugins for Fusion360, SolidWorks, and Onshape. This allows the tool to act as a "sidecar," where a user might generate a complex aesthetic surface in AdamCAD and then import it into SolidWorks for mechanical detailing.

2.3 Critical Reception and Market Realities

User sentiment analysis from forums and beta tests in late 2025 reveals a mixed landscape for AdamCAD. While hobbyists praise the tool for simple objects, professional engineers have voiced skepticism regarding its handling of complex assemblies. Feedback indicates that for critical components, the AI lacks "design intent"—it might create a shape that looks like a gear but lacks the precise involute curve geometry required for proper meshing in a gearbox.

Users have noted that for simple things (brackets, cases), it is faster than manual CAD, but for precision engineering, it still requires heavy human verification. The transition from free beta to paid subscriptions caused friction in the community, although the company has since introduced a more generous free tier to maintain user growth.

3. The Cognitive Layer: Leo AI and the Engineering Copilot

3.1 Beyond Geometry: The "Knowledge" Problem

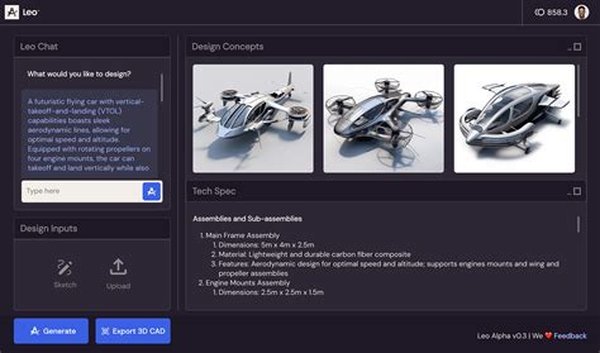

If Zoo handles the geometry and Adam handles the prototyping, Leo AI tackles the cognition of engineering. Leo is positioned not as a modeling tool, but as an "Engineering Copilot" designed for large firms dealing with complex systems. Its thesis is that the hardest part of engineering in 2026 is not drawing the line, but knowing where to draw the line.

3.2 The Large Mechanical Model (LMM)

Leo utilizes a proprietary Large Mechanical Model (LMM). This distinguishes it from generic LLMs like GPT-4. The LMM is trained on millions of engineering papers, standards (ISO, ANSI), and vendor catalogs.

- Legacy Knowledge Retrieval: A primary use case for Leo is "archaeology" within a company's own data. Engineering firms often re-design parts simply because they cannot find the drawing of a similar part designed 5 years ago. Leo connects to Product Lifecycle Management (PLM) systems to index a company's entire history. An engineer can ask, "Show me all bracket designs from the 2022 satellite project that supported over 5kg," and Leo retrieves the actual CAD files and specifications.

- Component Sourcing and BOM Automation: Leo connects to a database of over 120 million vendor parts. Instead of an engineer spending hours browsing McMaster-Carr or Misumi catalogs, they can describe the requirement ("I need a stepper motor with 5Nm holding torque that fits in a 40mm cube"), and Leo suggests available parts, checks stock, and even downloads the CAD model for the assembly. This transforms the Bill of Materials (BOM) creation from a manual data-entry task to an automated review process.

3.3 Return on Investment (ROI) and Enterprise Pricing

Leo AI's pricing reflects its high-value target audience. The Pro Tier is priced at $39/month, offering the "Engineering Copilot," concept generation, and standard part retrieval. The Business/Enterprise Tier is priced at $1800/year or custom quotes, unlocking deep integrations: internal company part search, PLM integration, and priority support.

The ROI pitch is simple: if Leo saves a senior engineer (billing at $150/hr) just 15 hours of work a year, it pays for itself. The company claims it can save engineers "hours each week," suggesting a payback period of less than a month for active users.

4. The Documentation Bottleneck: DraftAid and Swapp

4.1 The Persistence of 2D

Despite the hype around "Model-Based Definition" (MBD), 2D drawings remain the legal and contractual currency of manufacturing in 2026. A 3D model defines the shape, but the 2D drawing defines the tolerances, surface finishes, and inspection criteria. Creating these drawings is universally regarded as the most tedious, non-creative aspect of engineering.

4.2 DraftAid: Manufacturing Drawing Automation

DraftAid integrates directly into SolidWorks and Autodesk Inventor to automate the creation of 2D fabrication drawings. The platform claims to reduce drafting time by up to 90%. For a job shop producing hundreds of custom brackets a week, this is transformative. Instead of a drafter spending 20 minutes manually placing views and dimensions for each part, DraftAid does it in seconds.

The critical innovation in DraftAid is its ability to learn "Style." Every company dimensions differently—some use ordinate dimensions, others use baseline; some place notes in the top right, others in the bottom left. DraftAid trains on a company's existing repository of drawings to mimic their specific style, ensuring that the AI-generated drawings look like they were made by a human employee of that firm.

A simplified ROI analysis suggests that for a firm generating 300 drawings a month, DraftAid can save over 112 hours of labor, translating to roughly $8,400 in monthly savings (assuming a $75/hr loaded labor rate). This makes it one of the easiest AI tools to justify in a corporate budget.

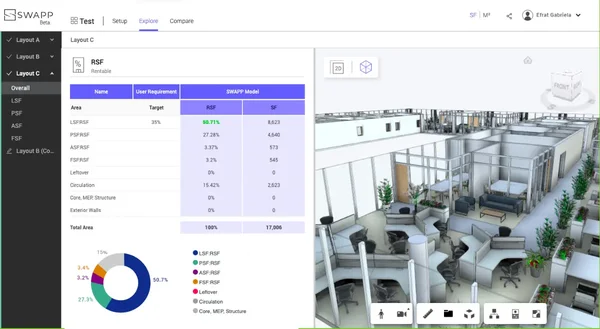

4.3 Swapp: The Architect's Assistant

While DraftAid focuses on mechanical parts, Swapp targets the Architecture, Engineering, and Construction (AEC) sector. Swapp takes a basic BIM model and automates the generation of full construction documentation—floor plans, elevations, reflected ceiling plans, and schedules.

In architecture, the ratio of "design time" to "documentation time" can be 1:5. Swapp aims to flip this, allowing architects to focus on the spatial experience while the AI handles the compliance documentation. The AEC industry faces a chronic shortage of qualified architects willing to do "grunt work." Swapp markets itself as the solution to this retention crisis, removing the burnout-inducing repetitive tasks that drive junior architects out of the profession.

5. The Physics Layer: Simulation and Generative Design

5.1 PhysicsX: The Speed of Inference

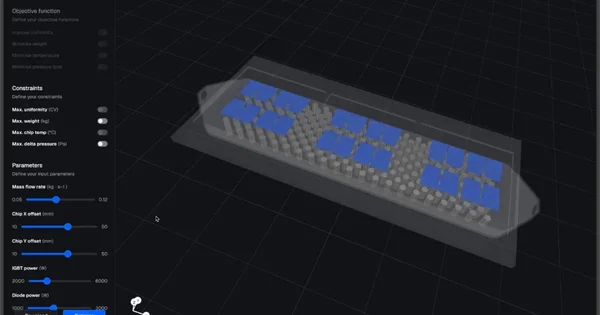

In high-performance industries (Aerospace, Formula 1, Automotive), geometry is useless without validation. Traditional Numerical Simulation (CFD, FEA) provides this validation but is excruciatingly slow. PhysicsX introduces Physics-AI, replacing the "solver" with an "inference model."

- LGM-Aero: PhysicsX has developed LGM-Aero (Large Geometry Model - Aero), a foundation model trained on over 25 million 3D shapes and their associated physics performance. This model allows engineers to drag a slider on a wing shape and see the aerodynamic drag coefficient change in real-time. It moves simulation from an "overnight batch process" to an "interactive design tool".

- Simulation Workbench: Recognizing that AI models are only as good as their training data, PhysicsX includes a Simulation Workbench. This module orchestrates traditional solvers to generate clean, structured data to train the AI. It acts as a bridge, allowing companies to use their trusted legacy solvers to "teach" the faster AI models.

- Real-World Impact: In scenarios like casting optimization or aerodynamic tuning, PhysicsX allows for the exploration of thousands of design variants in the time it used to take to test one. This "super-human" design space exploration is becoming a requirement for staying competitive in elite engineering sectors.

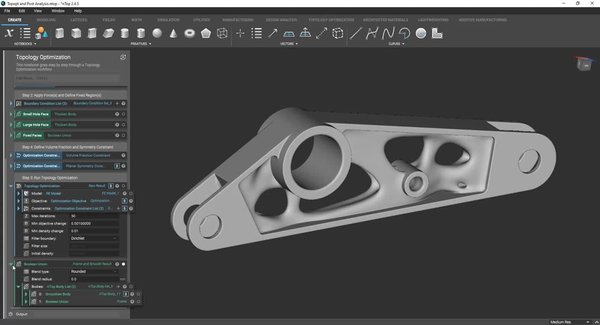

5.2 nTopology (nTop): Implicit Modeling Meets AI

nTopology (now often referred to as nTop) continues to dominate the field of Generative Design through Implicit Modeling. Unlike B-Rep or Mesh, nTop uses mathematical fields to define geometry. This allows for the creation of incredibly complex structures (gyroids, lattices, heat exchangers) that are mathematically lightweight but geometrically intricate.

In the 2025/2026 cycle, nTop has integrated machine learning directly into its optimization loops. This allows the geometry to "react" to physics fields (e.g., stress or heat) continuously. Instead of a static optimization, the part "grows" or "densifies" in response to simulated loads in real-time. This capability is crucial for Additive Manufacturing (3D Printing), where complexity is free, but design validation is expensive.

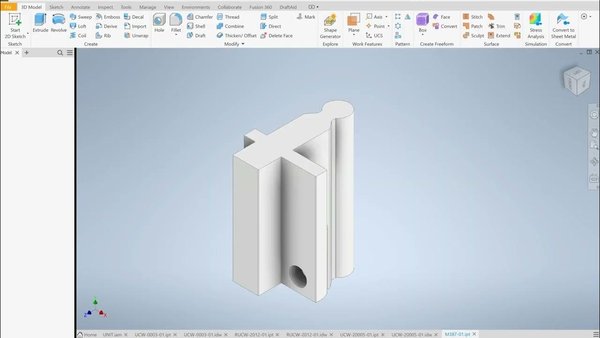

6. The Incumbent Response: Adaptation of the Giants

The legacy CAD giants—Autodesk, Dassault Systèmes, and Siemens—are not ceding the field. They are leveraging their massive installed bases and data moats to integrate AI as a feature rather than a standalone platform.

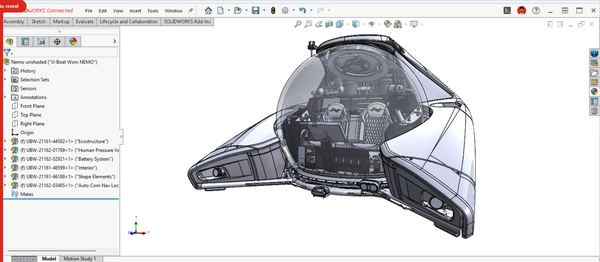

6.1 SolidWorks 2026: The "Aura" Era

SolidWorks, the standard-bearer for mechanical design, has launched SolidWorks 2026 with a heavy focus on AI integration. The centerpiece is Aura, an integrated AI assistant. Aura is not just a chatbot; it is deeply integrated into the 3DEXPERIENCE platform. It can guide users through complex workflows, summarize design changes from team members, and even retrieve "tribal knowledge" from the company's internal wikis and databases. Aura effectively lowers the learning curve for the notoriously complex software.

SolidWorks 2026 includes specific AI agents for tasks like "Fastener Recognition" (automatically populating assemblies with the correct bolts and washers) and "Drawing Automation" (auto-dimensioning views). These features target the same pain points as DraftAid but offer the advantage of being native to the platform.

Responding to the robust demand for privacy and stability, SolidWorks 2026 re-introduced and strengthened its "Unplanned Offline Mode." This acknowledges that while cloud connectivity is the future, reliable access is not guaranteed in many industrial environments.

6.2 Autodesk Fusion: The Cloud Native Advantage

Autodesk Fusion (formerly Fusion 360) benefits from being cloud-native from inception. Its AI updates in late 2025 focus on maturing Generative Design. Fusion's generative algorithms now deeply understand manufacturing constraints. The AI doesn't just suggest a shape; it suggests a shape optimized for 5-axis milling versus casting. This "Manufacturing Awareness" reduces the friction of taking a generative design from screen to machine.

Following the industry trend, Fusion has also rolled out automated drawing generation, allowing for the rapid creation of 2D assets from its cloud-stored models.

6.3 Siemens NX and PTC Creo

Siemens NX: The "AI Chat Copilot" in NX X Essentials focuses on predictive UI. It learns the user's patterns—if a user typically performs a "chamfer" after an "extrude," the AI predicts this and offers the tool, streamlining the clicks required for daily tasks.

PTC Creo 11: The focus here is on Generative Design for Additive. Creo 11 introduces constraints for "minimum feature size" and "bearing load support," ensuring that generative parts are robust enough for real-world duty cycles, not just aesthetic topology optimization.

7. Comparative Analysis: Market Dynamics

7.1 Pricing Models: SaaS vs. Consumption

The market is currently bifurcated by economic models:

| Platform | Model | Pricing Strategy | Best For |

|---|---|---|---|

| Zoo.dev | Consumption | $0.0083/second (Credit based) | Developers, Automated Workflows, Enterprise Infrastructure |

| AdamCAD | Freemium | Free Tier / Paid Sub for Exports | Makers, Hobbyists, Quick Prototyping |

| Leo AI | SaaS | $39/mo (Pro) / $1800/yr (Biz) | Professional Engineers, Consultants |

| SolidWorks | License/Sub | Annual Maintenance / Cloud Sub | Corporate Engineering Teams, Legacy Users |

| DraftAid | SaaS | Quote-based / Volume-based | Fabrication Shops, High-Volume Drafting |

7.2 The Technical Divide: Mesh vs. B-Rep

The most critical technical distinction in the 2026 market is the geometry type:

- Mesh (Polygonal): Used by many "Text-to-3D" art tools. Fast to generate, but "dumb." You cannot ask a mesh to "change hole diameter to 10mm" because the hole is just a collection of triangles.

- B-Rep (Boundary Representation): Used by Zoo, AdamCAD, and Legacy CAD. "Smart" geometry defined by mathematical equations. This is the only acceptable format for precision engineering. The ability of Zoo and AdamCAD to generate native B-Rep geometry is their primary "moat" against the flood of generic AI image generators.

8. Challenges and Risks: The Security Imperative

8.1 The "Black Box" Anxiety

The integration of AI into R&D has birthed a new security paradigm. Engineering firms are rightfully terrified of "IP Leakage." If a user uploads a classified drone design to a cloud AI for optimization, and that data is used to re-train the model, there is a theoretical risk that the model could memorize and reproduce that design for a third party.

Mitigation: Platforms like Leo AI and Zoo are aggressively marketing their security compliance (SOC 2, GDPR) and "Zero-Retention" policies. The promise is that the "inference" happens in a stateless environment—the AI sees the file for the split second it needs to do the work, and then instantly forgets it.

8.2 The Hallucination Risk

In text generation, a hallucination is a funny error. In engineering, a hallucination is a structural failure. If an AI "hallucinates" a material property (e.g., claiming Aluminum 6061 has the yield strength of Titanium), the consequences could be catastrophic.

Deterministic Validation: This is why the Hybrid Workflow is non-negotiable. AI tools in 2026 are increasingly being paired with deterministic "Physics Checkers." The AI generates the design, but a physics engine (like Ansys or Nastran) validates it before it can be released. PhysicsX explicitly builds this loop into their "Simulation Workbench" to ensure that AI speed does not come at the cost of physical reality.

9. Conclusion: The Hybrid Future

As we look toward the remainder of 2026, the hype cycle of "Generative AI" is settling into a phase of industrial utility. The dream of a "Star Trek Replicator"—where one speaks a command and a perfectly engineered machine appears—remains a distant fiction. However, the reality of the AI-Assisted Engineer is here.

Zoo.dev

Has successfully laid the rails for a new era of programmable CAD, breaking the monopoly of the legacy kernels.

AdamCAD

Has opened the door for non-experts to participate in physical design, though it remains a tool for prototyping rather than high-end production.

Leo AI & SolidWorks Aura

Are proving that the most valuable AI might not be the one that draws, but the one that remembers—unlocking the vast archives of legacy engineering data.

DraftAid & Swapp

Are quietly revolutionizing the economics of the industry by automating the lowest-value, highest-volume tasks of documentation.

The winning organizations in 2026 will be those that embrace this hybrid model: using AI to explore the vast space of possibility (generative design), using human judgment to define the intent (constraints and requirements), and using rigorous physics engines to validate the reality (simulation).

The engineer of 2026 is no longer a drafter of lines, but a conductor of algorithms.